If you ask a young person in China what enamel is, I think most people will not be able to answer.

An accidental opportunity led us to step into this ancient industry, which should not be abandoned by the times.

New era enamels with creative designs, each one is so incredible and still unique, we enjoy this feeling and have fun doing it

Let's be one of your best Chinese Partners

Enamel Mug · Enamel Bowl · Enamel Plate · Enamel Pot · Enamel Casserole · Enamel Saucepan · Enamel Kettle · Enamel Roaster etc.

Enamelware Wholesale Since 2017

- Professional

We have focused on the field of enamelware only for years, Please do not mind asking us any questions if you have trouble with enamelware, we will be happy if we can help you even if there is no cooperation at present. - Confidentiality

We will never disclose clients’ information to others, it’s a principle. We believe this is very important, regardless of whether the business is big or small. - flexibility

Over the years of enamel business, we almost can provide most of the enamel products. We will try our best to find the solution for you, we believe that a good start is very important, whether it’s for your business or our future orders. - Service

Good communication is a prerequisite for everything, we will adjust our service time according to your local time, Perhaps it may not cover the whole day, but we hope that most of the time, we can quickly reply to your Emails or WhatsApp message in time. - After-sales

Years of export experience — whether it’s quality or after-sales service, are very important, and a good reputation is an absolute prerequisite for doing business. We never evade issues and will actively handle them for you, we will carefully listen to your opinions and make improvements better and better.

Your trust and support will be the best encouragement for us

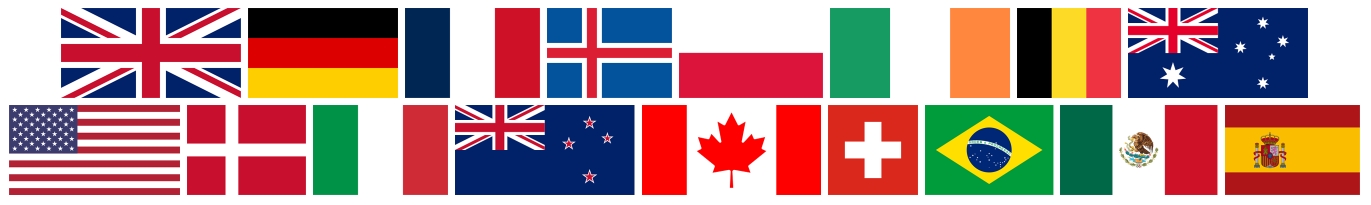

The United Kingdom · France · Poland Visit in May

Pls feel free to contact us, we will be happy to visit your company and communicate face-to-face, looking forward to seeing you! Cheers!

Enamelware Wholesale

NO.111,MIAONONG VILLAGE,YANGMING STREET,YUYAO,ZHEJIANG PROVINCE

WhatsApp: 0086-15757851662 Johnson Wu · Director Email: Johnson@waf-traders.com

NINGBO · CHINA Enamelware.TOP 4.0 | WAF Traders